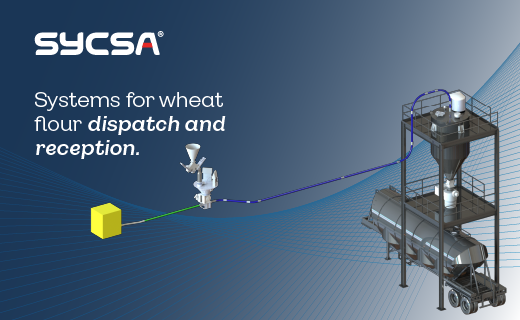

At SYCSA® we know that wheat flour is an essential product in the food industry, and as such, its correct handling and processing either at each stage of the milling or consumers process is crucial to guaranteeing the quality and safety of the product. For flour producers and consumers alike, it is also important to select the most appropriate dispensing and reception systems to use. In addition to product quality and safety, the most appropriate methods for shipping and unloading must also be considered.

That is why at SYCSA® we specialize in the design of packaging and unpackaging systems, advising our customers on selecting the presentation that best suits their needs, integrating efficient, safe processes that are aligned with capacity and logistics requirements.

Packaging and reception options.

We have developed solutions to meet a variety of needs, from presentations for the end consumer to bulk systems designed for industrial distribution.

1. Paper bags (paper sacks).

Paper sacks are used to package wheat flour when biodegradable and economical packaging is required. These bags are ideal for products that do not require a strict barrier against moisture and light and are intended for the end consumer for domestic use. These bags have a capacity ranging from 1 kg to 50 kg.

2. Polypropylene bags.

Polypropylene bags are used to package wheat flour when greater durability and protection against moisture and physical damage are required. They are ideal for storage and transport conditions that can be more demanding, such as environments with high humidity or long transport distances. These bags have a capacity ranging from 20 kg to 50 kg.

Some polypropylene bags are laminated or have an internal coating to provide an additional barrier against moisture.

3. Bulk bags.

Bulk bags, also known as FIBCs (Flexible Intermediate Bulk Containers), are used to package wheat flour when large quantities of product need to be shipped efficiently. They are ideal for large-scale operations and situations where significant volumes of storage and transport are required. Big bags have a capacity ranging from 500 kg to 1,500 kg.

4. Hopper Trucks.

The pneumatic dry bulk trailers are used to ship wheat flour when large volumes of product need to be transported efficiently and safely by road. They are especially useful for long distances and in situations where quick and controlled unloading is required. Some of the typical capacities of these trucks are 20, 25, and 30 tons.

The use of hopper trucks is an efficient option for large wheat flour producers and consumers and distributors seeking to optimize their supply chain and guarantee product quality until it reaches its destination.

Specialized systems: comprehensive solutions from SYCSA®

All our proposals cover the design and implementation of dispatch and reception systems that meet the specific needs of each customer, some of which may be:

- To package and receiving wheat flour in paper bags from 1 to 50 kg, we have several types of equipment and automated systems that ensure precision and efficiency in the process. Depending on the type of bag, all the systems can be complemented with peripherals such as metal detectors. These are devices that are integrated into the process to detect and remove any metallic elements that may be present in the flour.

- To handle wheat flour in bulk bags, we have specialized equipment that ensures an efficient and safe process. Our solutions include the filling and discharge structure and nozzle, weighing scales used to accurately weigh the amount of flour in each big bag, as well as metal detectors to locate and remove any metallic elements that may be present in the flour.

- We offer complete systems for dispatching and receiving wheat flour in bulk hopper trucks. These systems are designed to ensure efficiency and safety in every operation. These systems typically include pneumatic transport to move the flour from existing silos or hoppers in the mill to the designated dispatch area. Conversely, pneumatic transport is used to move the flour from the bulk hopper trucks to the existing silos in the bread or biscuit production facilities.

To quantify the amount of flour either shipped or received, we offer solutions ranging from high-precision weighing hoppers to gravity measurement systems. Finally, the truck is loaded using telescopic or retractable nozzles equipped with dust control systems that include filters and extraction mechanisms. This minimizes particle emissions during loading, promoting a safe environment and complying with occupational health regulations.

At SYCSA®, we offer solutions for all flour handling processes. Our designs ensure that materials are shipped and received efficiently, accurately, and safely, in compliance with all relevant standards and regulations.

Are you looking to optimize your wheat flour shipping and receiving systems? Contact us!